0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

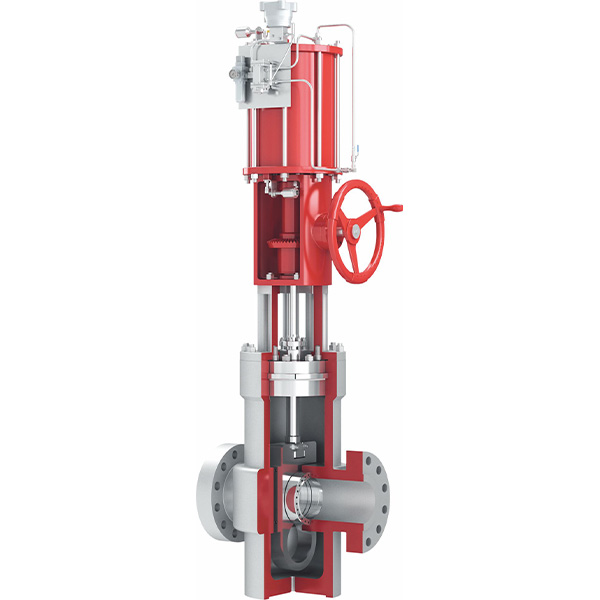

1. Petrochemical industry 2. high temperature and high pressure working conditions

1 High temperature resistance

2 High pressure resistance

3 Low flow resistance coefficient

4 full diameter can pass through the ball pig

5 Long service life

| Structural Characteristics | Instructions |

|---|---|

| Double group packing sealing | double group packing sealing structure to ensure the reliable sealing of the valve stem, and the sealing fat can be injected into the packing to supplement the packing material to ensure the sealing performance of the valve stem. |

| Can prevent the middle cavity pressure | when the valve chamber due to temperature changes, the medium pressure can push the valve seat for automatic pressure relief. |

| Full path design | with diversion hole structure, full path structure design, small flow resistance coefficient, small pressure loss, can clean the pipeline. |

| Long service life | the valve with the diversion hole structure, no matter fully open or fully closed state, the valve plate and the valve seat always contact with each other, the sealing surface is not directly washed by the medium, so as to prolong the service life of the valve. |

| Reliable seal at the valve cover | the connection between the valve cover and the valve body adopts wood sealing structure, using all metal sealing ring, high temperature resistance, the higher the pressure, the better the self-sealing, can prevent the seal failure due to pressure or temperature change. |

| stem surface extrusion process | through the advanced surface extrusion technology to improve the surface hardness of the valve stem, reduce the roughness, can reduce the valve in the switching process of the packing wear, and prevent the stem strain. |

| Prevent high temperature jamming | rationally design the coordination gap between the valve cap and the valve stem to prevent the high temperature deformation of the valve stem from jamming. The valve seat is pre-tightened by the cylindrical spring, and has a reasonable gap with the valve body to prevent high temperature jamming. |

| High temperature resistant valve seat design | the valve seat adopts hard sealed valve seat, the sealing surface can be welded according to the medium temperature or customer demand, the valve seat and valve body seal adopts flexible graphite, which can be high temperature resistant but also have fire prevention function. |

| The middle cavity is not easy to collect dust | when the valve is fully open or closed, the middle cavity in the valve is in a closed state, and the impurities in the medium are not easy to deposit in the middle cavity. |