0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

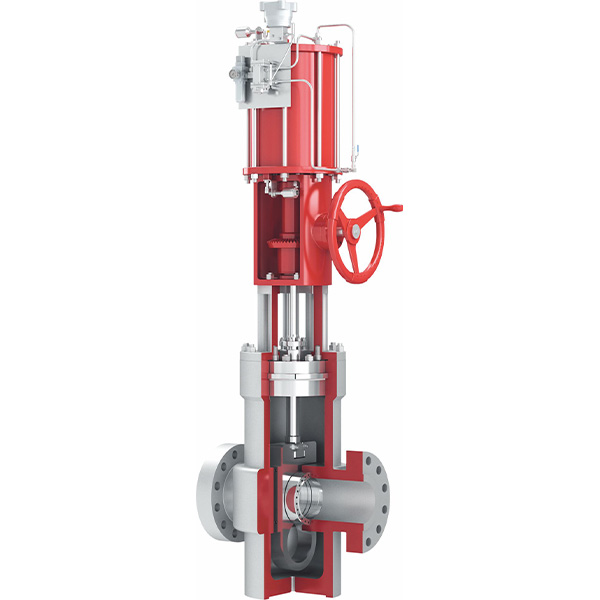

1. Hydrogenation unit 2. coal chemical industry 3. harsh conditions

1 Prevent high temperature rise to death

2 Top installation design, can achieve online maintenance

3 Two-way forced sealing, sealing is more reliable

4 full diameter can pass through the ball pig

5 Zero leakage can be achieved

6 Flexible installation orientation

| Structural Characteristics | Instructions |

|---|---|

| Top installation design | after the pipeline system decompression. Online inspection and repair are available to simplify the maintenance. |

| Packing loading design | double sets of low leakage packing and loading disc spring design to avoid valve leakage due to frequent opening. |

| K-type plate structure | unique K-type plate structure, more than the conventional wedge-type double parallel gate valve opening force is smaller, in high temperature will not die due to different material expansion ratio, so the reliability in the high temperature pipeline is higher than the traditional parallel double gate valve. |

| Integrated structure of valve seat and valve body | according to the requirements of coal chemical industry, the valve seat is made into an integrated structure with the valve body to avoid the phenomenon of valve jamming caused by impurities entering the valve seat gap. |

| Full path design | full path diversion hole design, easy to online cleaning, smooth flow channel, small flow resistance coefficient, no pressure loss. |

| Diversion hole structure design | the diversion hole structure can ensure that when the valve is fully open or fully open, the gate plate and the valve seat sealing surface are always in contact, to ensure that the sealing surface will not be washed by the medium, so as to prolong the service life. |

| Automatic pressure relief | The valve has an automatic pressure relief device to ensure the safe operation of pipelines and equipment. |

| Double forced seal design | valve plate and seat sealing surface overwelded hard alloy, can achieve complete bidirectional forced seal, can ensure the reliability of sealing. |