0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

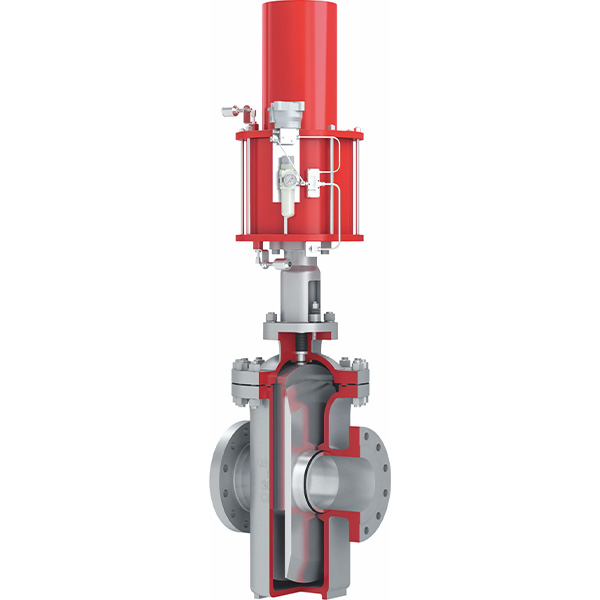

1. Hydrogenation unit 2. catalytic unit 3. The polysilicon industry

1 Long service life

2 Reliable sealing

3 The cavity in the valve body is not easy to accumulate the material

4 Prevent high temperature rise to death

5 fire-protection design

| Structural Characteristics | Instructions |

|---|---|

| Wide sealing surface | there is a wide sealing surface between the skateboard and the valve seat, even if part of the sealing surface is damaged, the surrounding surface can continue to play a sealing role,So the valve has a long service life. |

| Design of dust cover | dust cover is set in the valve core. During the process of fully opening the valve and switching, the small medium will not enter the valve chamber. |

| Valve seat scraper design | valve seat scraper design, the movement between the skateboard and the valve seat is shear movement, can scrape off the dirt stuck on the skateboard. |

| Unique spray welding process | the valve body flow channel and the valve interior use supersonic spraying (HOVF) carbide technology to improve the wear resistance of the valve. |

| Protected sealing surface | the valve is not washed by the medium when closed or open. |

| Packing loading and sealing | the packing place adopts the disc spring loading design, and the long-term sealing is more reliable. |

| Parallel double gate structure design | using parallel double gate structure, the spring between the two gates will not appear the valve lock phenomenon under high temperature condition. |

| Full diameter design | using the diversion hole diameter structure design, can realize the ball clearance pipe. |