0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

1. Transportation pipeline 2. Loading platform

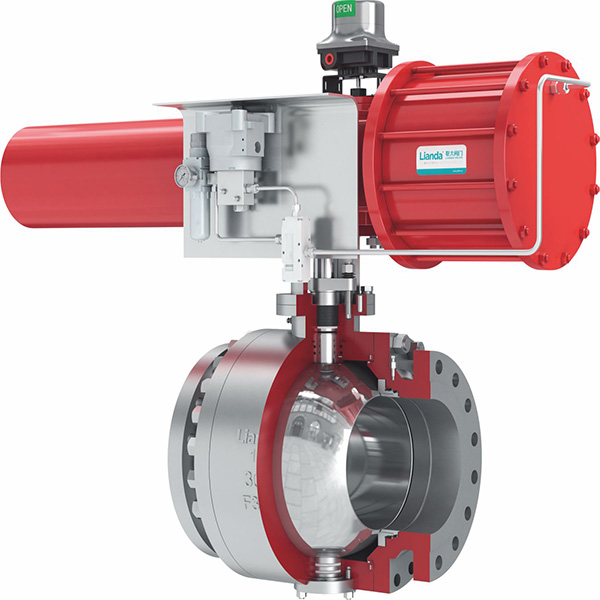

1 Multiple seal, with a more reliable seal

2 Low switching torque

3 Long service life

4 Stable performance

5 fire-protection design

| Structural Characteristics | Instructions |

|---|---|

| Double thrust bearing design | two coated inner stem bearing rings act as thrust bearings with rotating movement. They use super wear-resistant coating, which can reduce the torque of the valve, and prevent the valve from sticking after using for a long time, and prolong the service life of the valve. |

| External leakage point seal | middle flange, lower fixed shaft, upper packing letter are hard metal to hard, metal winding pad, O-ring / panplug seal / fire graphite rope and other multiple seals, which can also be sealed in the case of fire, with more reliable seal. |

| Upper bearing design | the valve stem and fixed shaft are equipped with high quality self-lubricating wear-resistant long bearing, which can keep the valve shaft coaxial and eliminate the load caused by the valve switch or valve vibration. |

| Anti-static design | anti-static structure design, connect the sphere, valve stem and valve body to prevent fire due to static aggregation. |

| Anti-blowing valve stem | the valve stem adopts high corrosion resistance super alloy, and conducts vacuum heat treatment to improve the surface hardness and prevent strain. Upper packing function structure, to prevent the valve stem blowing out of injury, can achieve online replacement of filler. |

| Seal of stem fill | valve stem with low leak fill (through API 622 certification), lip seal ring, emergency fat injection seal multiple seal, with more reliable seal. |

| packing loading and sealing | the packing place adopts the disc spring loading design, and the long-term sealing is more reliable. |

| Seal at the valve seat | the valve seat is equipped with fat injection hole, fireproof graphite rope, dustproof structure, with fire prevention, dustproof and reliable sealing characteristics. Graphite seal ring or panplug seal can be selected as the seat seal ring according to the actual operating temperature. |

| Spherical seat sealing surface | sphere-seat sealing surface wide, can reduce the dynamic contact stress, extend the service life of the valve. For different harsh working conditions, spray welding of different high strength carbide layer. At the same time, the sealing structure of DBB, DIB-1 and DIB-2 can be designed according to customer needs. |