0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

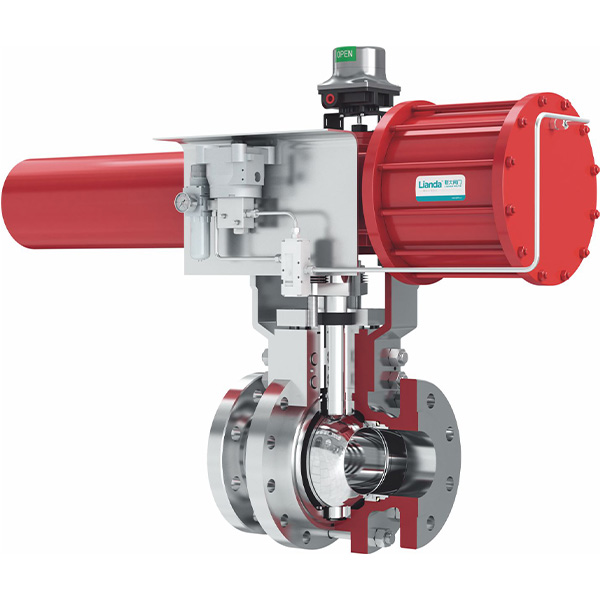

1. Gassifier lock bucket system

1 Resistance to erosion

2 Chlorine resistance

3 fire-protection design

4 Antiaccumulated slag hold dead

5 Long service life

6 Fluid resistance is small

| Structural Characteristics | Instructions |

|---|---|

| Ball club integrated design | the ball and the valve stem are integrated to ensure the neutrality of the sphere, to avoid the ball away from the stem after frequent switch phenomenon. |

| Fixed design of the valve body to the middle sphere | the valve body adopts a two-segment center structure, and the sphere adopts the fixed ball structure, which not only ensures the concentricity of the sphere, but also realizes the low torque of the valve opening. |

| Advanced spherical valve seat hardening technology | in order to ensure the reliable sealing of the valve at various temperatures and pressures, according to the different working conditions and requirements of users, supersonic jet welding, nickel based spray welding, powder sintering and other processes, can meet the vast majority of harsh working conditions. |

| Ball hardening process | when the valve is opened, the position of the ball mouth is often washed by the medium. In order to improve the service life of the ball, 20mm Stai alloy is welded at the ball mouth. |

| Scraper design on the seat | the scraper structure design is adopted on both sides of the sealing surface, so that the sphere and the seat have the self-cleaning function in the switching process, effectively prevent the accumulation and adhesion of particles between the sphere and the valve seat, and ensure the smooth and continuous valve operation, not stuck. |

| Double seal design at the valve seat | there are two seals between the valve seat and the valve body, one can prevent the slag from flowing from the valve chamber into the seat sealing cavity, one can prevent the slag from the flow into the seat sealing cavity, which not only protects the disc spring, but also realizes the double seal of the valve seat and the valve body. |

| Inherent fire-proof structure | the valve sealing surface adopts metal to metal sealing structure, the packing adopts flexible graphite, and the gasket uses 316 + flexible graphite structure, therefore, the valve can ensure reliable sealing even in the case of fire. |

| Inherent anti-static structure | the valve body, seat and sphere of the lock valve close contact, naturally formed electrostatic channel. |