0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

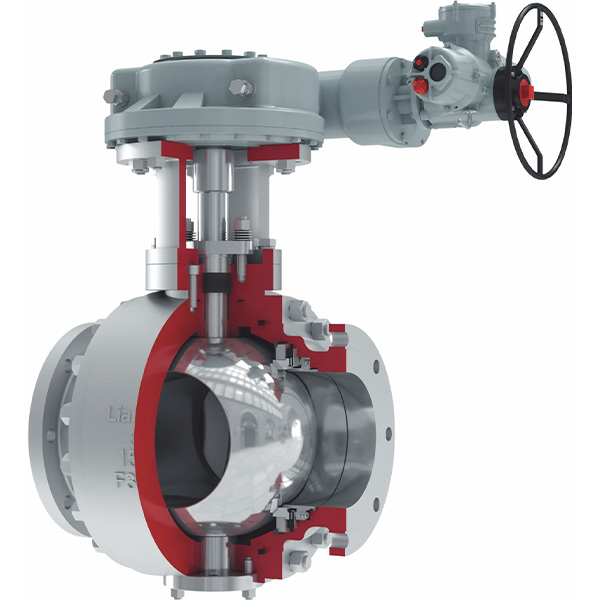

1. vapour line 2. Hot oil pipeline

1 High temperature resistance

2 High temperature resistance

3 Reliable sealing

4 fire-protection design

| Structural Characteristics | Instructions |

|---|---|

| Anti-blowing valve stem | adopt high corrosion resistance super alloy, and conduct vacuum heat treatment to improve the surface hardness and prevent strain. Upper packing function structure to prevent the stem from blowing out. |

| External leakage point seal | middle flange, lower fixed shaft, upper packing function are hard metal to hard, metal winding pad double seal, can also be sealed in the case of fire, the seal is more reliable. |

| New sealing structure of valve seat | the U-type metal sealing ring made of elastic metal material has certain elasticity, which can compensate the thermal expansion and cold contraction between the parts through the elastic deformation when the temperature change, so as to effectively avoid the phenomenon of jamming or leakage caused by the temperature change. |

| Long bearing design | the stem and fixed shaft are equipped with high quality self-lubrication wear-resistant long bearing, which can keep the valve shaft coaxial and eliminate the load caused by the valve switch or valve vibration. |

| Packing loading and sealing | the packing place adopts the disc spring loading design, and the long-term sealing is more reliable. |

| Double thrust bearing design | two bearing rings with hardening treatment act as thrust bearings with rotating movement, which can reduce the torque of the valve, prevent the tightness of the valve after using for a long time, and prolong the service life of the valve. |

| Design of pressing fixing device | pressing fixing device is composed of pressing ring, support ring, pressing screw and four open ring, with simple structure and convenient disassembly. At the same time, the pressing force of the pressing ring on the U-shaped metal sealing ring can also be adjusted by rotating the pressing screw. |