0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

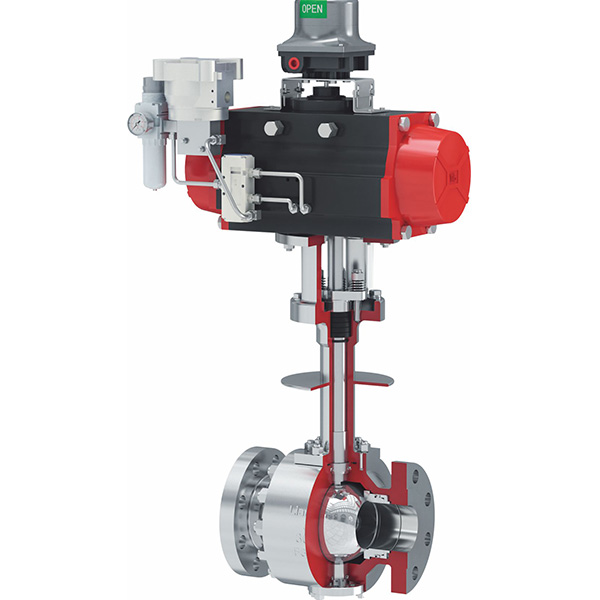

1. LNG 2. ethylene project

1 low temperature resistance

2 Valve degreasing treatment

3 Low switching torque

4 Reliable sealing

5 fire-protection design

6 Strictly ban oil

| Structural Characteristics | Instructions |

|---|---|

| Anti-blowing valve stem | upper packing function structure to prevent the valve stem from blowing out, can realize online replacement of filler. |

| Dripping plate design | welding a dripping plate on the packing letter, this can prevent condensate into the cooling layer, avoid or reduce the corrosion of the cooling layer, improve the service life of the cooling layer, and packing function after welding the drip plate, will make the packing function and air natural convection heat exchange area greatly increased, cooling loss of valve body. |

| External leakage point seal | middle flange, lower fixed shaft, upper packing letter with metal hard to hard, metal winding pad, panplug seal multiple sealing seal is more reliable. |

| Long bearing design | the stem and fixed shaft are equipped with high quality self-lubrication wear-resistant long bearing, which can keep the valve shaft coaxial and eliminate the load caused by the valve switch or valve vibration. |

| Packing loading and sealing | the packing place adopts the disc spring loading design, and the long-term sealing is more reliable. |

| Stem seal | valve stem with low leakage packing (through API 622 certification), panplug seal, reseal, more reliable seal. |

| Design of long neck packing letter | The design of long neck packing letter avoids the failure of the valve stem at the filling sealing place in the filling place, and the sealing failure. |

| Double thrust bearing design | two coated stem bearing rings act as thrust bearings with rotating movement. They use ultra-wear-resistant coating, which can reduce the valve torque, prevent the valve from jamming or crawling after use for a long time, and prolong the service life of the valve. |

| Strict oil ban measures | all parts of the valve are degreasing in strict accordance with the degreasing process, and can be assembled only after ultraviolet light test and strip wiping test. Dry and pure nitrogen should be used as the valve test medium. |