0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

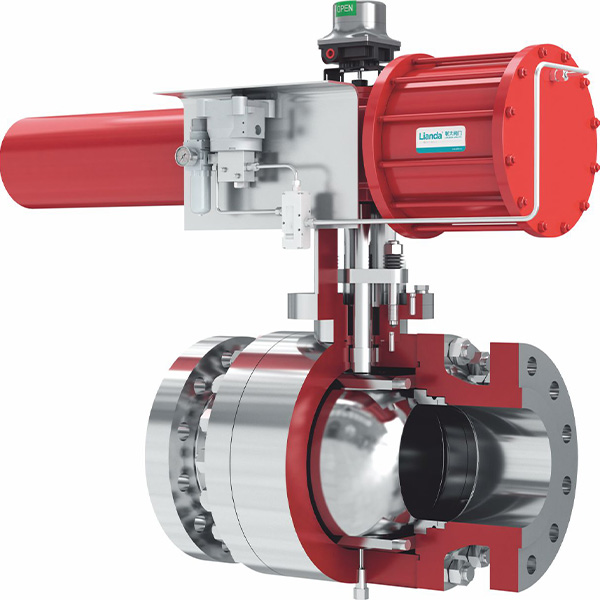

1. Special rail ball valve for black water and gray water 2. Hydrogenation track ball valve 3. Special rail ball valve for the catalyst 4. LNG plant 5. ethylenel project

1 Low switching torque

2 Available for online repair

3 Prevent the middle cavity cup

4 Full pass diameter design

5 reliable seal

6 Inherent fire proof design

7 Zero leakage can be achieved

| Structural Characteristics | Instructions |

|---|---|

| Hardening of the stem guide groove | when the stem switch, the guide groove will be subjected to a large load. Therefore, the guide groove needs to do the corresponding hardening treatment. |

| Double stem guide pin | The hard stem guide groove and the stem guide pin cooperate with each other to lift and rotate the stem. |

| Filler loading sealing | the packing place adopts the disc spring loading design, and the long-term sealing is more reliable |

| Top type design | simplify the maintenance. |

| Prevent leakage | the top assembly structure has less leakage points, the valve body valve cover is sealed with metal sealing ring, good sealing, and has fire prevention function. |

| Single valve seat design | can realize the two-way sealing without closed middle cavity, to avoid the problems of middle cavity pressure and middle cavity cup. |

| Switch without friction | because the rail ball valve sealing surface switch without friction, rotation is particularly easy, the service life is much greater than the conventional valve. |

| Hard sealing surface of anti-wear valve core | according to different working conditions, the surface of the valve core is suitable for supersonic spray welding, which can meet the application in very demanding occasions. |

| Mechanical wedge seal | The inclined plane at the lower end of the stem provides a mechanical wedge tightening force to ensure continuous tight sealing. |