0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

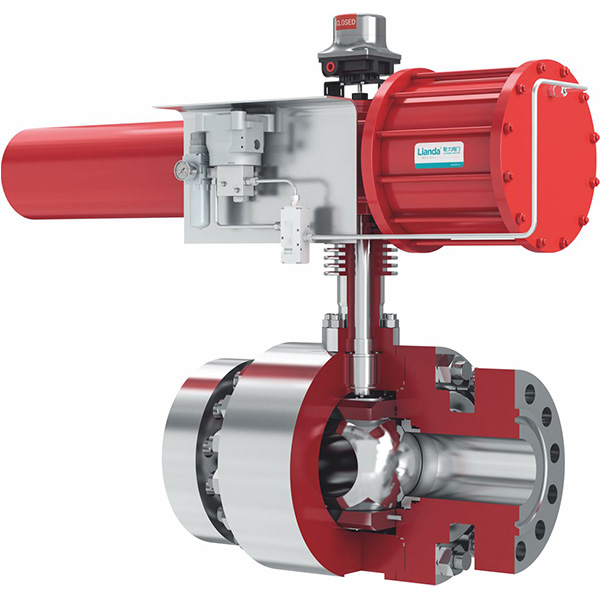

1 Reliable sealing

2 Long service life

3 Low switching torque

4 Prevent high temperature to hold dead

| Structural Characteristics | Instructions |

|---|---|

| Thermal expansion analysis, prevention of valve leakage | by using professional three-dimensional software for the thermal expansion analysis of the valve interior, by changing the size of the maximum deformation area of the thermal expansion of the support plate, can prevent the support plate to open the auxiliary valve body leakage. |

| Advanced sphere seat hardening technology | the alloy layer on the sealing surface of the sphere and the valve seat produces peeling and strain in the high temperature residue medium is one of the main causes of valve leakage, by calculating and adjusting the width of the valve seat sealing surface, and using supersonic jet welding WC, can solve this problem, thus greatly improving the service life of the valve. |

| Special structure design, prevent the valve open level astringent | sphere sealing surface, valve stem bearing cavity, seat sealing cavity easy to produce scale is one of the main reasons of the valve open level astringent, through the valve stem bearing cavity and valve seat sealing cavity design dust structure, on the valve seat design scraper structure, can solve the problem of valve card. |

| Reasonable selection of valve materials | the thermal expansion of the valve parts under high temperature condition is the main reason of the valve locking at high temperature, through the thermal expansion coefficient of the material to select the material of the valve parts, can solve the problem of high temperature locking. |