0577-5891 7200

0577-5891 7200

Online Consultation

Online Consultation

RichScan

RichScan

Scan QR code and consult us

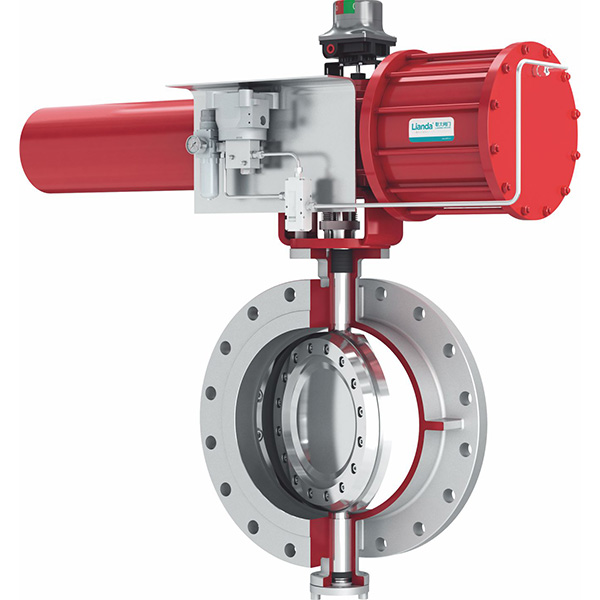

1. High-temperature pipeline 2. Steam lines for electric power 3. Negative pressure vacuum condition 4. Special for coal chemical vaporizer

1 High temperature and high pressure resistance

2 Large Cv value

3 Reliable sealing

4 Long service life

5 Low switching torque

6 Fire protection design

| Structural Characteristics | Instructions |

|---|---|

| Stem seal | Low leakage packing (API 622 certified) for a more reliable seal at stem. |

| Simple appearance of the butterfly plate, the intensive design of the butterfly plate parts | the thickness of the butterfly plate is greatly reduced, and the valve has a larger Cv value, which makes the flow capacity greatly improved. |

| Valve seat seal ring universal design | Seal ring universal design, maintenance does not need to be done, can be replaced directly on site. |

| Fireproof structure design | the valve seal adopts metal to metal or metal to graphite structure, and the filler adopts flexible graphite to ensure the sealing reliability of the valve in the case of fire. |

| Packing loading seal | the packing place adopts disc spring loading design, long-term sealing is more reliable. |

| Long bearing design | The self-lubricating long bearing at the valve stem can keep the valve stem coaxial, eliminate the valve switch or valve vibration load, reduce friction torque, protect the valve stem. |

| All-metal sealing ring | greatly extend the service life of the valve, improve the working condition, can be used in the working condition containing a small amount of solid particle medium, reduce the number of maintenance. |